uses of charpy impact test|charpy impact test formula : companies Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact test results help manufacturers and engineers determine whether the material is suitable for its . WEB23 de fev. de 2024 · Painkiller: Hell & Damnation is a singleplayer and multiplayer first-person FPS game in the Painkiller series. General information. Official forums. Steam Community Discussions. Availability • Link. All versions require Steam DRM. A free demo can be downloaded from Steam via direct link (allow Steam popup): steam://install/223370.

{plog:ftitle_list}

Resultado da 24 de set. de 2021 · 43 jogos. 11 vitórias. 20 empates. 12 derrotas. 40 gols marcados. 42 gols sofridos. 16 clean sheets. Londrina pelo Campeonato .

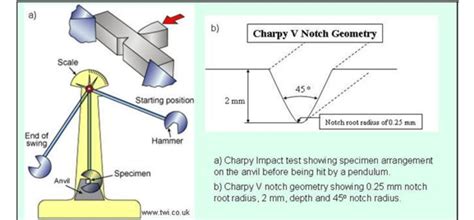

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact test results help manufacturers and engineers determine whether the material is suitable for its .Material impact toughness can be measured by various types of test such as the Charpy V-notch impact test, Izod test or K IC test. The most commonly used test is the Charpy impact test (see .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

The Charpy impact test, sometimes called a V-notch test, is a comparative-style test used to define a material’s impact strength by determining how much energy is required to fracture a pre-prepared and standardized .Beyond measuring resistance to impact, the Charpy impact test offers dynamic insights into how materials behave under stress. The test allows for predicting a material’s fracture behavior by introducing a controlled notch or pre-crack in .

The Izod / Charpy Impact Test measures the amount of energy absorbed by a material during fracture. This test is conducted by striking a standard-sized specimen with a hammer released from a specific height and .The Charpy or CVN impact test remains the most convenient and the most widely method used to determine the fracture properties of ferritic steels. This includes the determination of the .

Charpy impact testing, or V-notch testing, is an evaluation of a material’s strength and performance under impact conditions. It involves a pendulum with a pointed hammer on the end swinging and hitting a machined .In a Charpy impact test to ISO 148-1, a notched metal specimen is severed using a pendulum hammer. For the test, the metal specimen is centered on the supports in the pendulum impact tester. The notch is exactly across from the .The Charpy impact test is still used throughout sectors to assess material toughness, from construction and manufacturing to engineering and beyond. This test offers practical insights into how materials respond to sudden, dynamic .

How to use a Charpy impact tester. One of the most common tests performed with pendulum impact testers is the Charpy test, which has also earned these machines the designation of Charpy impact testers or Charpy impact . Charpy impact testing is one of the most popular methods used to evaluate the toughness of a material, which is typically measured in ft-lbs. To perform a Charpy impact test, the material to be tested must first be machined to a specific set of dimensions as determined by one of the national or international testing standards. The machined . Charpy impact testing, or V-notch testing, is an evaluation of a material’s strength and performance under impact conditions. It involves a pendulum with a pointed hammer on the end swinging and hitting a machined piece of metal cooled to the required temperature to measure the amount of fracture at that temperature.

This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D Solutions Library operated by KEYENCE introduces examples of shape measurement problems and the latest solutions for various industries, .How to Use Charpy Impact Test Results. Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact test results help manufacturers and engineers determine whether the material is suitable for its intended use. 1. Energy Absorption

The Charpy test is most commonly used to evaluate the relative toughness or impact toughness of materials and as such is often used in quality control applications where it is a fast and economical test.

Charpy Impact Test is the most commonly used test which is used for determining the amount of forces that are absorbed by materials when it reaches the point of fracture. This amount of energy gives the analysis of the notch hardness of material. In this test, .Charpy to ISO 179-1 is the preferred test method on plastics within the standard for single-point data ISO 10350-1. The test is ideally performed on unnotched specimens with edgewise impact (1eU). Should the specimen not break during the test, any subsequent tests are performed with notched specimens.The test is similar to the Charpy impact test but uses a different arrangement of the specimen under test. The Izod impact test differs from the Charpy impact test in that the sample is held in a cantilevered beam configuration as opposed to a three-point bending configuration.

charpy notched impact strength

Charpy Impact Test. In a Charpy test, a notched specimen is struck by a pendulum hammer swinging from a known height. The energy absorbed by the specimen during fracture is calculated by the difference in the pendulum’s height before and after impact. This energy absorption measures material toughness.

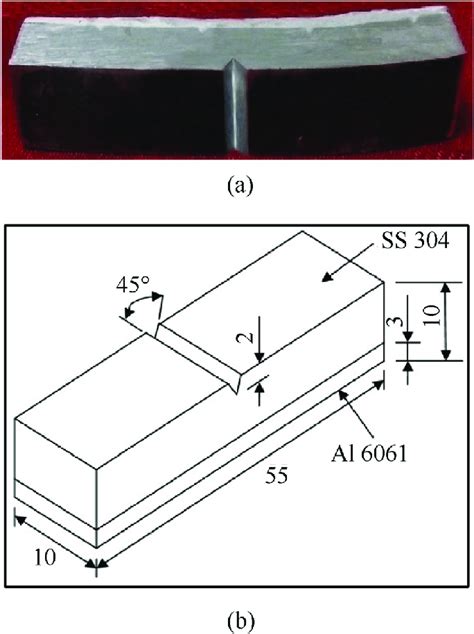

Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient . The Izod / Charpy Impact Test represents a pivotal evaluation method in the material science industry, serving as a fundamental measure of a material's toughness and resistance to impact at varying temperatures. This .

ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the .

The value of energy absorbed is read directly from a dial on the machine. A typical impact testing machine is shown in Figure. 1. Figure 1. Schematic of a Typical Charpy Impact Testing Machine. In carrying out a test, the specimen .Charpy Test Standards: Charpy impact testing is typically carried out following standards like ASTM E23, ASTM A370, or ISO 148. Although the test is more commonly associated with metals, there are also specific standards tailored for plastics .The Charpy impact test. The standard Charpy test uses a 10 mm × 10 mm specimen with a 2 mm deep V notch, placed upon an anvil and broken by a pendulum weight. The energy absorbed is measured by the height of the swing of the pendulum after fracture. Charpy Impact test is used for evaluating the toughness and impact resistance of materials, particularly metals like steel. This test stands as a critical assessment in materials engineering.Its significance lies in simulating real-world scenarios where sudden loads or impacts can occur. The test utilizes a pendulum to deliver a controlled .

To determine the material resistance to impact from a swinging pendulum. Apparatus Required. Charpy testing machine, a rod of mild steel and a rod of carbonate steel. Charpy Test Specimens. Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be : The Charpy test is used to determine the resistance capacity of metal (steel) specimens against the sudden impact of a pendulum that swung from a certain height. The Charpy impact is also known as the Charpy V-notch test because the specimen used in this test is cut at a certain depth in a ‘V’ shape.

What is the Charpy Impact Test? The Charpy impact test is a widely known test famous for its accuracy in measuring metallic and plastic materials. SB Russell and George Charpy introduced this in the 20th century to measure the strength of the material. How is this test performed? It comprises a weighted pendulum that is dropped on the material.

The Charpy test is a pendulum-based test introduced by Georges Charpy and S. B. Russell. The test was valuable in understanding the material fracture in ships during world war II. The Charpy test consists of a pendulum and a hammer of known mass attached to it. The pendulum swings and hits the notched specimen to observe the energy transfer. Table 1. l~4echanical properties ofthe investigated 18X2MFA steel at ambient temperature 1/3t _< t < 2/3t 18X2MFA T-direction T-L-position (cover material) CJYS GtJrs A CV LE "I'68J ] T0.qmm wall thickness [SPa] [SPa] I%] [J] [mm] [~ 1 [~ 634 732 20 156 1,66 16 25 nomenclature: cvs - yield stress, O'U'I'S-ultimate tensile strength, A .

charpy impact test sample dimensions

The Izod impact test is similar to the Charpy impact test but uses a different arrangement of the specimen under test. The Izod impact test differs from the Charpy impact test in that the sample is in a cantilevered beam configuration instead of a three-point bending configuration.

Basic principle and practical procedure of the Charpy impact test - Testing machine, test specimen - Basic principle, impact energy measurement - Temperat.

Resultado da 15 de dez. de 2023 · Casino nyheder. Velkommen til DkCasinoSpot nyhedssiden. Vi dækker alle nyheder, der sker i online gambling-industrien. Her finder du alle de seneste nyheder om danske online casinoer, samt nye casino bonusser og kampagner. Hvis en populær softwareudvikler frigiver .

uses of charpy impact test|charpy impact test formula